Chevron Pump Vibration Resolved Through MagnaDrive Coupling Systems

MagnaDrive highlights how their coupling products helped Chevron pump vibration. Discover more about this project and process.

MagnaDrive highlights how their coupling products helped Chevron pump vibration. Discover more about this project and process.

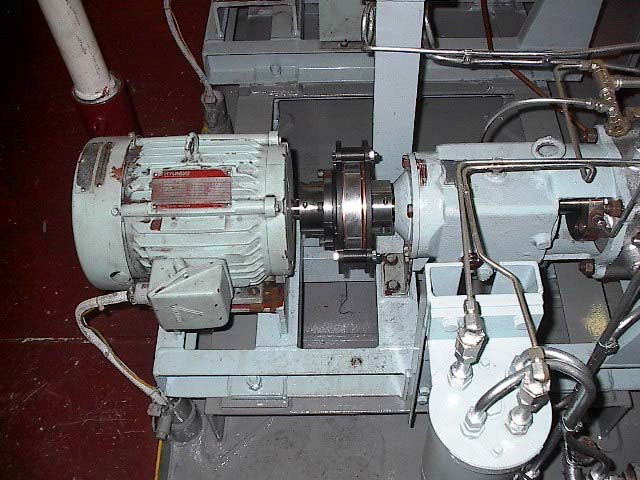

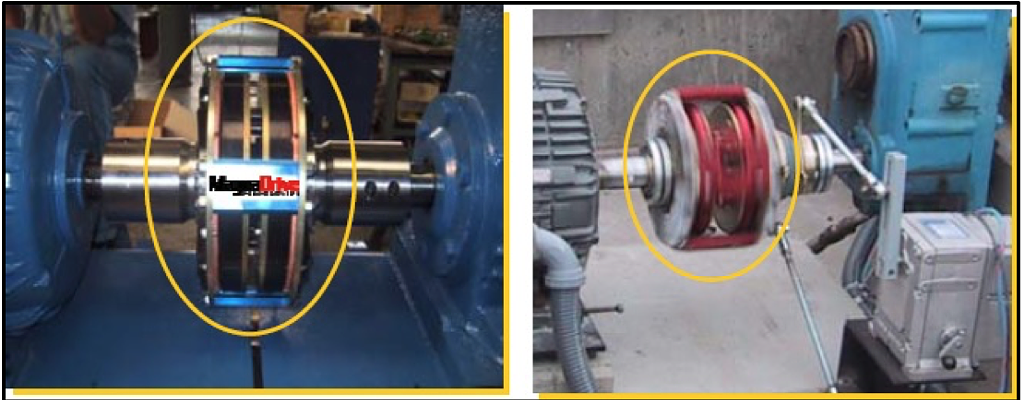

Conventional bolted couplings are known to be a leading cause of maintenance challenges in the modern industrial plant. These products require alignment, can transfer vibration to equipment and may cause equipment reliability issues over time. It’s why many plant operators are now turning to permanent magnetic shaft couplings in response. In this latest post, we’ll

Companies throughout the industrial marketplace are now experiencing the damage caused by vibrations between the couplings and their connected equipment. The vibration limits system efficiency and enhances the need for equipment maintenance over the long-term. Our team at MagnaDrive has great experience resolving vibration-related coupling issues and our recent case study involving our work with

Case study of the City of San Antonio and how we used magnetic couplings to minimize conveyor drive vibration levels. Read more here!

MagnaDrive will be presenting a paper titled “Newly Developed Magnetic Coupling products for Energy Saving and Reliable Operation with Easy Maintenance” at the Middle East Rotating Machinery Technology and Innovation Conference & Showcase (ME RoTIC) – The event is scheduled to take place on 25th – 27th September, 2018 in Dubai, United Arab Emirates. ME RoTIC

In the company’s newest post, the team at MagnaDrive highlights their latest case study. The study focuses on their work with Minnesota Power. Explore more, here.

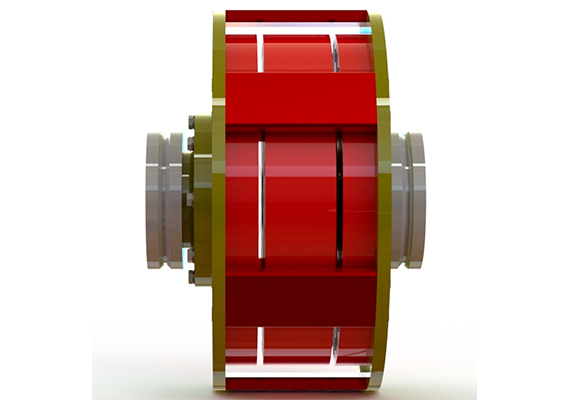

SYNCHRA is targeted primarily for maintenance intensive applications and includes high speed rotating equipment. The SYNCHRA is a magnet to magnet high performance non-slip and non-contact magnetic coupling. The highest power to size ratio of all of MagnaDrive’s product offerings, it is designed for up to 1500 HP applications. SYNCHRA introduces many benefits versus other

Not every design calls for a MagnaDrive motor coupling – but you will know when yours does. MagnaDrive products use a proprietary and patented magnetic process for torque transfer, centered around our own high-power Neodymium-Iron-Boron magnets. They are mounted on either side of the motor shaft, with an air gap in between. By varying the

Click here to read more