City of Eugene

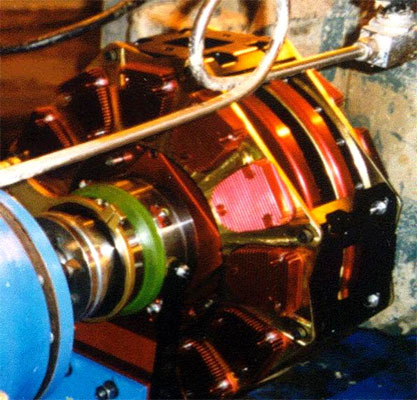

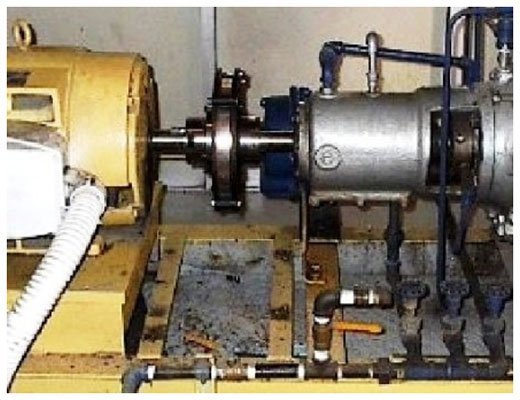

Situation The lateral forces of the belt drive on the gearbox shaft created an unbalanced load – this created a maintenance headache and cost the City approximately $10,000 per year in repairs. The Solution MagnaDrive proposed the installation of a MGD 18/250 coupling to replace the entire belt system. The proposal was accepted and the coupling installed.