Nippon Paper

Situation

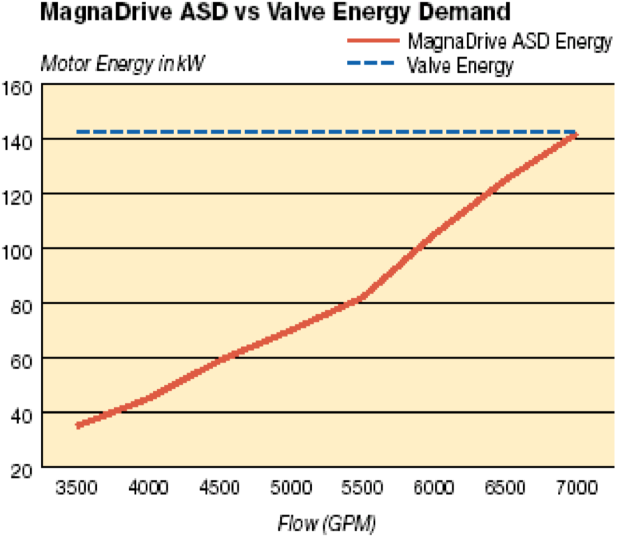

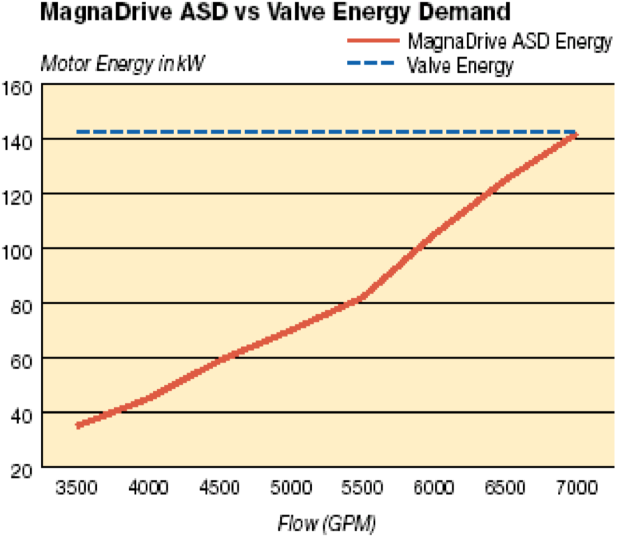

- The pumping system was designed to provide 7,000 GPM to the treatment process, yet the process only requires 4,800 GPM.

- Multiple bypass and throttling valves were installed to control flow

- The use of these valves resulted in the waste of energy

- The pumps were required to start at full load from a dead stop.

- This caused flow surges through the system’s piping; it also caused the pump motors to overheat

The Solution

- MagnaDrive’s ASDs were chosen to replace the valves due to their rugged nature and price-competitiveness

The Results

- Nippon Paper was able to maintain 4,800 GPM to the clarifier.

- This resulting in 80 kW demand savings over the original valve-based system.

- The Mill saves about $32,000 per year in energy savings alone (approx. 700,000 kWh).

- The Mill also saves $15,000 per year in maintenance costs.