City of San Antonio

Learn how MagnaDrive helped the city of San Antonio Public Services to reduce the vibration readings in their conveyor drive system by 80%

Learn how MagnaDrive helped the city of San Antonio Public Services to reduce the vibration readings in their conveyor drive system by 80%

Grand Hyatt Hotel was looking for a solution to it’s water pressure problem, since it was insufficient. Learn here how Magnadrive helped!

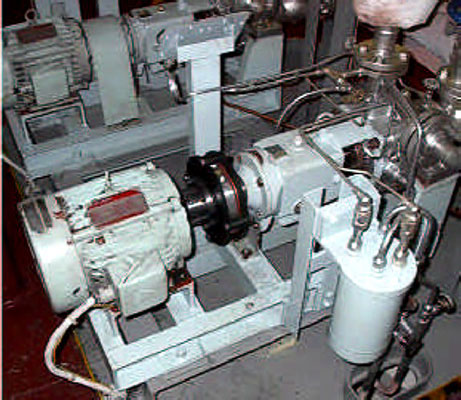

MagnaDrive Corp. installed a VTX-07 coupling on a Chevron oil transfer pump while it was in port for routine service. Learn about the details here!

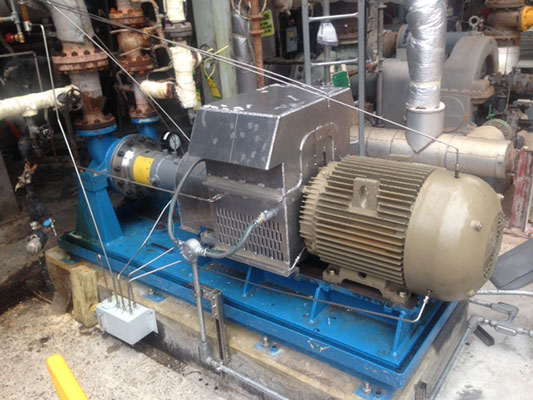

The Army was looking to install MagnaDrive couplings to resolve their vibration issues/ save energy. Read more about how we made it possible.

Read more on how MagnaDrive designed a mine dewatering system for Diavik Mines and the challenges faced with the extreme weather conditions.

Learn more about the problems that South Walker Creek coal mine was having with their valve and how MagnaDrive’s techonology helped.

ExxonMobil, an oil and gas corporation, needed to find a solution for their pump’s speed problem. Learn how MagnaDrive helped.