Ponderay Newsprint

Situation

Only the de-inking portion of the process (approx. 12 minutes per hour) required full system flow of 3,200 GPM. Without speed control, however, the mill ran their pumps at full capacity all the time, which is extremely inefficient.

The Solution

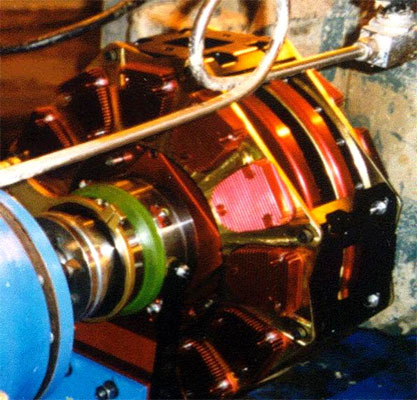

- In order to reduce the pump speed (while maintaining a required 50 PSI line pressure), Ponderay selected a 18.5 Adjustable Speed Drive. This allowed them to run the system at full flow when required, but also allowed a reduction in flow.

The Results

- The ASD allows the pump to run at maximum speed for the 12 minute de-inking process (3,200 GPM) and at a lower speed (corresponding to 1,600 GPM) for the remaining 48 minutes per hour.

- Energy demand dropped from 173 kW to 65 kW (a 62% reduction in energy).

- The ASD also dramatically reduced pump vibration and allowed Ponderay to remove several bypass valves from the system.