Condition Monitoring with MagnaDrive: Advantages of IIoT in 2020

The Industrial Internet of Things (IIoT) is how the Internet is emerging in the physical world. Smart manufacturing tools (sensors, software, monitoring devices) allow today’s industrial products to create, measure and optimize potential outcomes. This can improve areas such as energy efficiency as well as energy costs.

MagnaDrive provides some of these tools with its adjustable speed drives (ASDs). The IoT merges hardware with software, and provides an  avenue for software to interact with the physical world. It also creates a way for different pieces of hardware to communicate with each other.

avenue for software to interact with the physical world. It also creates a way for different pieces of hardware to communicate with each other.

An IIoT device is more than just a product with software; it’s more than a “smart” or “connected” device. At the heart of all IIoT devices is data analytics. When these devices become networked together and the collective data is analyzed for patterns, IIoT can become an invaluable tool in the manufacturing plant.

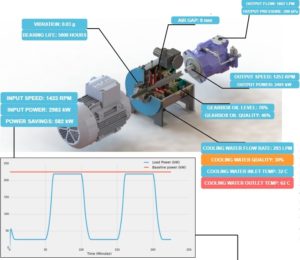

MagnaDrive is currently developing IIoT products with other industrial device manufacturers. The company has designed new magnetic couplings to integrate with customers’ control and monitoring systems. Sensor technology can collect torque, vibration, and temperature information in real time, and the collected data can be sent directly to the customers’ control system.

With proper algorithms, the collected data can be analyzed to generate valuable information.

The Value of IIoT

There are four elements to an IIoT product: the physical hardware, the mathematical model, the application, and the data analytics. The mathematical model is a description of the product and the system it exists inside. For MagnaDrive, that model is made up of the torque curves, heat transfer coefficients, and fan curves that the engineers are used to working with. The application is the software on the product and in the cloud that manipulates the model, actuates the product, and moves the data. The analytics, or data science, is the process that  turns raw data into something valuable.

turns raw data into something valuable.

These resources open up many new opportunities for a maintenance engineer. For example, vibration data can be transferred to a mathematical model for predicting bearing life. With the right algorithm in place, the engineer can be alerted when it’s time to grease or replace old bearings.

But there are unknown uses waiting to be found in the data as well. As more data is collected from each product, data scientists will be able to determine new opportunities. It quite possible that data being collected at the component level today may not offer any real value now, but could be incredibly important in the future as the system evolves.

The following is a list of potential benefits from incorporating MagnaDrive’s IIoT ASD:

- Temperature data will allow the ASD to protect itself from overheating.

- Predictive Maintenance: Sensor data with analytics will alert maintenance engineers when they are needed, therefore reducing maintenance overhead for the customer.

- Torque and speed data will provide process information to the customer that they might not have had before.

- Any data anomalies could indicate that something is not right with the system. An automatic alert could be sent to the customer, letting them know things should be investigated.

- The IIoT network could turn off a motor, or disengage the ASD, to protect the system if it detects a serious problem.

- The product could collect information on live energy prices from the Internet, and then use that information to adjust its speed in an effort to optimize the customers’ process or minimize energy use.

- An ASD could use historical information on electric grid brownouts to predict when it is best to engage or disengage.

- The customer will be able to monitor and control an ASD remotely. Their phone or computer becomes the HMI, removing the need for a costly HMI that is rarely used.

Most of the benefits fall under the umbrellas of predictive maintenance or process optimization. Accenture provides some quantitative benefits on these: Operational efficiency is one of the key attractions of the IIoT, and early adopters are focused on these benefits. By introducing automation and more flexible production techniques, for instance, manufacturers could boost their productivity by as much as 30 percent. Predictive maintenance of assets is one such area of focus, saving up to 12 percent over scheduled repairs, reducing overall maintenance costs up to 30 percent and eliminating breakdowns up to 70 percent.

The main point is that IIoT condition monitoring systems at the component level will continue to advance in the coming years. MagnaDrive is open to working with OEMs to develop smart devices to meet these industrial market demands.

For further information on predictive maintenance visit XMPro website.

No Comments :