MagnaDrive Upgrades Three Paper and Pulp Applications

The paper and pulp industry has been thriving and will continue to do so in the coming years as innovation and technology helps to meet the changing demands of this unique manufacturing segment. Improving operational efficiency while minimizing costs is paramount when it comes to paper and pulp applications. The components used in these applications face hazardous environments, strict regulations, aging infrastructure, and high-energy consumption.

MagnaDrive offered VTX-11 couplings to replace rigid couplings in one pump system for the paper and pulp industry. In two other examples, the installation of adjustable speed drives (ASDs) for pumps led to lower maintenance costs, significant energy savings and numerous system efficiency gains.

Ponderay Newsprint

The Ponderay Newsprint mill opened in 1989. It produced newsprint for publishers along the West Coast and the Midwest. The company also exported to the Asian and South American markets.

De-inking in the pulp and paper industry is the process of eradicating printing ink from paper fibers of recycled paper to make it a deinked  pulp. It can be achieved by a combination of mechanical and chemical means by utilizing a range of different technologies.

pulp. It can be achieved by a combination of mechanical and chemical means by utilizing a range of different technologies.

Full system flow (3,200 gpm) was required during the de-inking process at Ponderay (approx. 12 minutes per hour). Without speed control, however, the mill ran their pumps at full capacity all the time, which was extremely inefficient.

In order to reduce the pump speed (while maintaining the required 50 psi line pressure), Ponderay selected a MagnaDrive 18.5 Adjustable Speed Drive. This allowed them to run the system at full flow when required, but also allowed a reduction in flow.

The ASD allowed the pump to run at maximum speed for the 12-minute de-inking process (3,200 gpm) and at a lower speed (corresponding to 1,600 gpm) for the remaining 48 minutes per hour. Energy demand dropped from 173 kW to 65 kW (a 62% reduction in energy). The ASD also dramatically reduced pump vibration and allowed Ponderay to remove several bypass valves from the system.

NW Forest Products

NW Forest Products harvests and sells useful wood products in order to keep forests better, healthier, and in a more productive condition. The company was forced to replace condensate pumps multiple times per year due to extremely high vibration caused by thermal expansion of the pump shafts.

The company was forced to replace condensate pumps multiple times per year due to extremely high vibration caused by thermal expansion of the pump shafts.

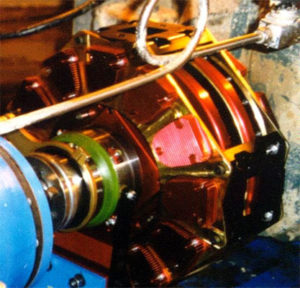

MagnaDrive proposed the installation of VTX-11 couplings as replacements for the existing rigid couplings. Removal of the old couplings and installation of the VTX-11 took less than one hour. Instead of being forced to replace each pump 3-4 times per year, the pumps have thus far not been replaced at all. Vibration levels dropped by 70% Each VTX-11 coupling has saved the customer approximately $24,000 in maintenance costs since they no longer require multiple pump replacements per year.

Nippon Paper

The Nippon Paper Group produces a variety of materials from wood, a renewable resource, and develops a diverse range of businesses, including paper and paperboard, under the slogan of “shaping the future with trees.”

While the pumping system Nippon utilized was designed to provide 7,000 gpm to the paper treatment process, the process really only required 4,800 gpm. Multiple bypass and throttling valves were installed to control flow. The use of these valves resulted in the waste of energy. The pumps were required to start at full load from a dead stop. This caused flow surges through the system’s piping; it also caused the pump motors to overheat. MagnaDrive suggested its ASD to minimize maintenance costs and provide significant energy savings.

The MagnaDrive ASD is available in sizes ranging from 5 to 4,000 horsepower and speeds up to 3,600 rpm. Lower maintenance and operating costs are a result of transferring torque from motors to driven equipment across an air gap without shaft-to-shaft physical connection. This “disconnected connection” provides reduced vibration that increases bearing and seal life.

MagnaDrive’s ASDs were chosen to replace the valves at Nippon Paper due to their rugged nature and price-competitiveness. Nippon Paper was able to maintain 4,800 gpm to the clarifier. This resulted in 80 kW demand savings over the original valve-based system. The mill saved about $32,000 per year in energy savings alone (approx. 700,000 kWh). The mill also saved $15,000 per year in maintenance costs.