Sustainability

Make sustainability your priority.

MagnaDrive is the world leader in sustainable magnetic couplings for industrial and commercial use.

MagnaDrive provides component alternatives that allow significant energy savings.

We can replace plastic, oil, greased and other disposable and even hazardous couplings to significantly reduce maintenance and waste.

Magnadrive products are sustainable and made of 100% recyclable material (Steel/Iron, Aluminum) that contribute to the circular economy.

MagnaDrive can replace VFD’s, (and eliminate PCB’s) also eliminate plastic couplings , oil couplings (Hazardous waste), greased couplings and other disposable couplings.

Reduce maintenance significantly *( extend bearing life cycle, eliminate leaky pumps, and extend the life of MagnaDrive connected rotating equipment).

Contribute to the circular economy and optimize energy efficiency.

Start your sustainable journey with MagnaDrive today.

By global estimate, power generation and heavy industry are responsible for nearly 50% of the world’s carbon emissions today. In order to combat these high numbers, power generation and industrial producers will need to create alternatives to processes and new technologies that will boost recycling.

That’s where we come in.

Our MagnaDrive ASDs and Emax coupling products allow customers across the globe to experience long-lasting quality equipment, up to a 70% reduction in energy consumption and decreased system complexity.

Energy Savings Up to 70%

With our Air Gap technology, we eliminate friction and save energy where it’s used the most. Our alternative couplings and adjustable speed drives are nearly 100% efficient with no additional energy loss from ancillary equipment.

Our torque transfer solutions can be customized to meet the unique needs of your system, resulting in significant energy savings.

MagnaDrive can play a role in the global net-zero emissions targets by 2050.

MagnaDrive is committed to taking action toward this goal.

We help industries across the globe realize higher performance, lower operational and maintenance costs, and up to 70% energy savings.

MagnaDrive products pass 4 out of 5 of the criteria from the US Green Building Council, including:

✓ Optimized energy efficiency

✓ Use of sustainable materials

✓ Lower maintenance

✓ Ecosystem protection

Lower Maintenance Costs

Did you know that over 80% of rotary equipment failures are caused by vibration-related issues?

By eliminating vibration transfer between shafts, our patented Air Gap technology also greatly reduces your risk of equipment trouble. MagnaDrive couplings emit less than average EMI, protecting your critical equipment from electrical damage and your wallet from costly repairs.

Improved Reliability

Since MagnaDrive’s magnetic rotor and conductor rotor don’t touch, there are no grease points or worn out connections. This extends your motor life and protects your investment.

Elements such as bearings and seals are all constructed from corrosive-resistant materials, coatings and durable electroplating — and expected to last over 20 years. Plus, MagnaDrive’s tech is tough and dependable in all types of weather conditions, ranging from -40° F to 150° F.

Customer Comments Regarding Sustainability:

“At the end of the test we conclude that replacing the flexible couplings with MagnaDrive MGE not only resulted in significant savings in the avoided maintenance cost but also saved us energy.”

“Control is much greater than any VFD. The large footprint is not needed, and harmonics are not an issue. We don’t have to replace couplings annually and deal with aligning the pumps and motors. The noise disappeared as soon as we started it. MagnaDrive… WOW!”

“We don’t have to replace couplings annually and deal with aligning the pumps and motors. The cavitation noise we lived with for ten years disappeared as soon as we started the MagnaDrive ASD.”

“We are extremely pleased with the energy savings we are getting with the MagnaDrive Adjustable Speed Drives. With the stability, reliability and reduced maintenance cost requirements of the system; we are excited about moving forward with other applications in the mill.”

PARTNERSHIPS AWARDS

Coming Soon

RESOURCES

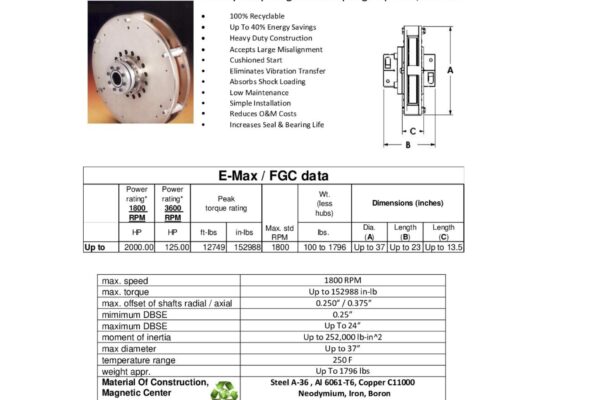

Technical Data Sheet - E-Max/FGC Magnetic Coupling

Non-Contact Power Transmission For Energy And Maintenance Savings

Heavy Duty Magnetic Couplings Up To 2,000 H.P.

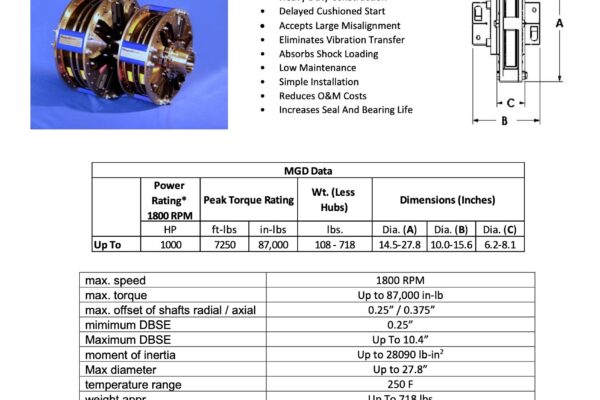

Technical Data Sheet - MGD Magnetic Coupling

Non-Contact Power Transmission Cushioned Start And Maintenance Savings Heavy Duty Magnetic Couplings Up To 1,000 H.P.

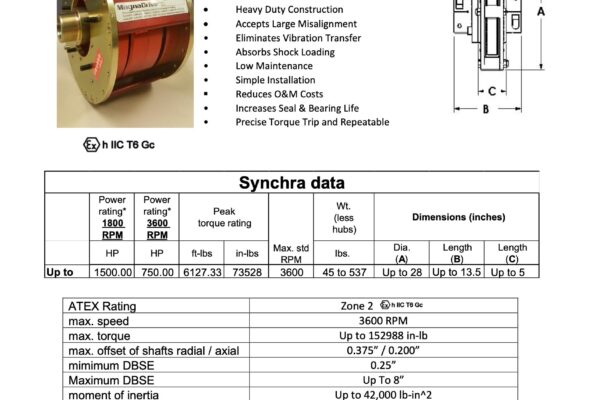

Technical Data Sheet - Synchra / MZ Magnetic Coupling

Non-Contact Power Transmission For High Speed / ATEX

No Slip Heavy Duty Magnetic Couplings

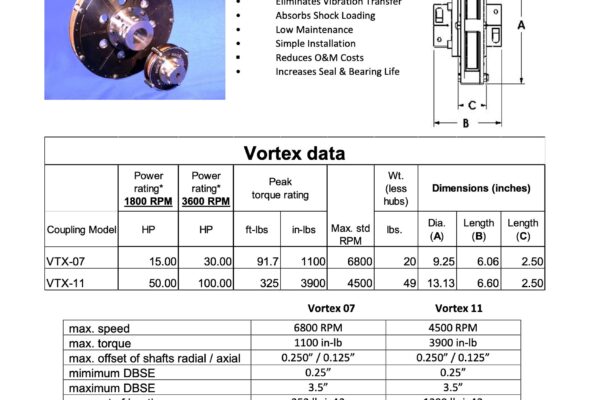

Technical Data Sheet - Vortex Magnetic Coupling

Under 100 HP Non-Contact Power Transmission

Standard Magnetic Coupling for Centrifugal Applications