Enhancing Petrochemical Performance

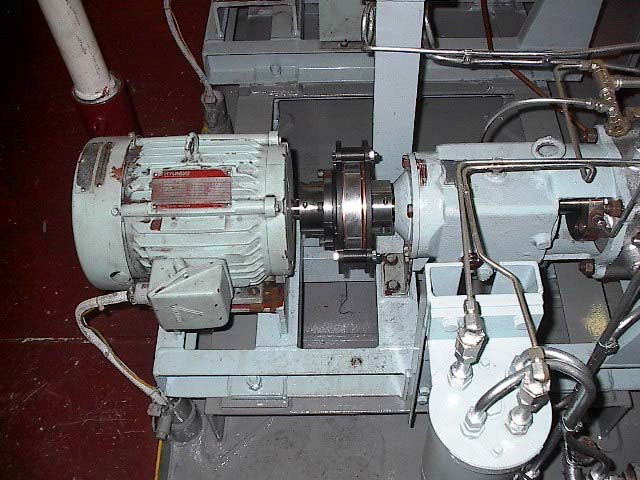

Equipment in the petrochemical industry includes centrifugal style fans, material pumps, belt conveyors, water/wastewater pumps, and more for chemical, raw material, and petroleum/petrochemical processes. In many circumstances this equipment requires significant maintenance, high-energy consumption, and unnecessary labor costs. The following case studies examine how petrochemical plants upgraded their equipment with MagnaDrive ASDs to enhance operating